NiAl cladding powder with strong bonding strength

Description

We are proud to introduce two products based on NiAl powder: KF-2 and KF-6. These two products use different ratios of NiAl powder and have unique characteristics and applications.

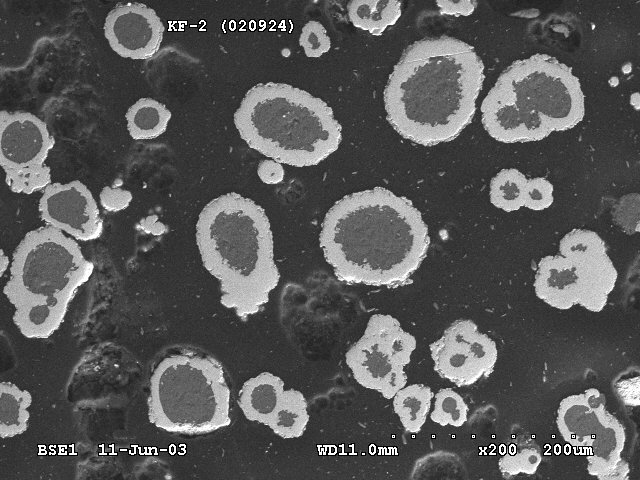

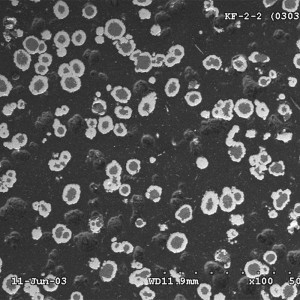

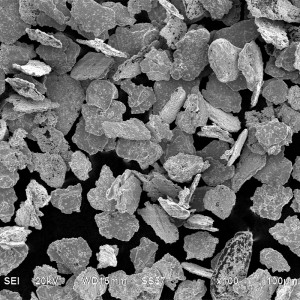

KF-2 uses NiAl82/18, which contains 82% Ni and 18% Al. This product is suitable for applications with a maximum operating temperature of 650°C. It provides a dense, machinable, oxidation-resistant, and wear-resistant coating with self-bonding properties. There is always an exothermic reaction during the spraying process, which results in excellent bonding strength superior to Ni5Al material. KF-2 is suitable for repairing and re-manufacturing machinable carbon steel and corrosion-resistant steel, and can also be used for bonding layers of ceramics and wearable materials.

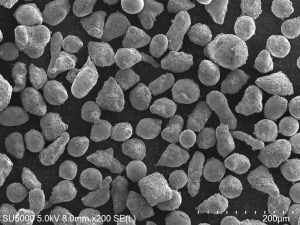

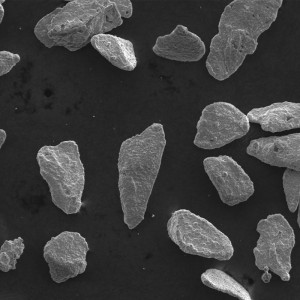

KF-6 uses NiAl95/5, which contains 95% Ni and 5% Al. This product is suitable for applications with a maximum operating temperature of 800°C and can be applied using various spraying methods such as flame, APS, and HVOF. It also provides a dense, machinable, oxidation-resistant, and wear-resistant coating with self-bonding properties. There is always an exothermic reaction during the spraying process, resulting in excellent bonding strength. KF-6 can also be used for repairing and re-manufacturing machinable carbon steel and corrosion-resistant steel, as well as bonding layers of ceramics and wearable materials.

In summary, both KF-2 and KF-6 are NiAl powder-based products that offer excellent bonding strength and wear resistance. KF-2, which contains a lower percentage of NiAl powder (NiAl82/18), is suitable for applications with a maximum operating temperature of 650°C, while KF-6, with a higher percentage of NiAl powder (NiAl95/5), can handle higher temperatures up to 800°C and can be applied using various spraying methods. Both products are ideal for repairing and re-manufacturing machinable carbon steel and corrosion-resistant steel, as well as for bonding layers of ceramics and wearable materials. The choice between KF-2 and KF-6 depends on the specific requirements of the application and the maximum operating temperature required.

Similar products

| Brand | Product Name | AMPERIT | METCO/AMDRY | WOKA | PRAXAIR | PAC |

| KF-2 | NiAl82/18 | 404NS | ||||

| KF-6 | NiAl95/5 | 282 | 956450NS | NI-109 | 906 |

Specification

| Brand | Product Name | Chemistry (wt%) | Hardness | Temperature | Properties & Application | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Al | W | Mo | Cr | Al2O3 | MoS2 | WC | C | Fe | Ni | |||||

| KF-2 | NiAl82/18 | 20 | Bal. | HRC 20 | ≤ 800ºC | •Flame, APS, Max. operating temperature 650°C.

•Dense and machinable oxidation resistant and wear resistant coating. |

||||||||

| KF-6 | NiAl95/5 | 5 | Bal. | HRC 20 | ≤ 800ºC | •Flame, APS, HVOF, Max. operating temperature 800°C

•Dense and machinable oxidation resistant and wear resistant coating |

||||||||

| KF-20 | Ni-MoS₂ | 22 | Bal. | HRC 20 | ≤ 500ºC | •Used for movable sealing parts and grindable sealing rings •It can be used as low friction material |

||||||||

| KF-21T | Ni-Graphite 75/25 | 25 | Bal. | HRC 20 | ≤ 480ºC | •Flame, Max. operating temperature 480°C 1. Wearing materials of turbo compressor •Applicable to nickel alloy and steel parts •Products with high graphite content are suitable for titanium parts without edge •High graphite content will enhance the lubrication performance •High nickel content will improve erosion resistance •Similar products are different due to different OEM specifications |

||||||||

| KF-22T/R | Ni-Graphite 60/40 | 50 | Bal. | HRC 20 | ≤ 480ºC | |||||||||

| KF-21R | Ni-Graphite 75/25 | 25 | Bal. | HRC 20 | ≤ 480ºC | |||||||||

| KF-45 | Ni-Al2O3 77/23 | 23 | Bal. | HRC 40 | ≤ 800ºC | •Flame,APS, irregular

•It can be used to melting crucible, terminal sealing surface and mold surface as protective layer |

||||||||

| KF-56 | Ni-WC 16/84 | Bal. | 12 | HRC 62 | ≤ 400ºC | •Flame,APS, irregular

•Resistance to hammering, erosion, abrasion and sliding abrasion |

||||||||

| KF-50 | Ni-WC10/90 | Bal. | 10 | HRC 62 | ≤ 400ºC | •Flame, irregular

•Resistance to hammering, erosion, abrasion and sliding abrasion |

||||||||

| KF-91Fe | Fe-WC | 4 | 27 | 9.5 | Bal. | 5.5 | HRC 40 | ≤ 550ºC | •Flame, APS, irregular, Max. operating temperature 815°C.

•Wear resistant coating material, which can be used for tank brake pad repair |

|||||

| KF-110 | NiCr-Al 95/5 | 5 | 7.5 | Bal. | HRC 20 | ≤ 800ºC | •Flame, APS, Max. operating temperature 980°C.

•Plasma spraying with self bonding |

|||||||

| KF-113A | NiCrAl-CoY2O3 | Cr+Al:20, Ni+Co:75 | HRC 20 | ≤ 900ºC | •APS,HVOF, irregular, Max. operating temperature 980°C.

•It is applicable to the repair of high temperature bonding layer or wear / improperly processed parts |

|||||||||

| KF-133 | NiMoAl | 5 | 5 | Bal. | HRC 20 | ≤ 650ºC | •Self bonding, common hard coating for bearing application •Tough, with good corrosion resistance and impact performance •Used for machine parts, bearing seat and valve |

|||||||

| KF-31 | Ni-Diatomite 75/25 | •Flame,APS, irregular, Max. operating temperature 650°C.

•For grindable seal coating, including movable seal parts, grindable seal rings, low friction materials |

||||||||||||