Copper Base Alloy with excellent electrical and thermal conductivity

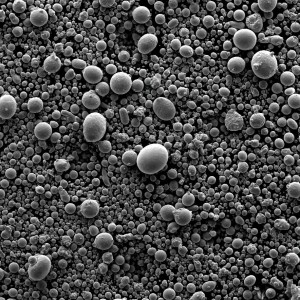

Description

Excellent electrical and thermal conductivity, non-magnetic and usable for EMI shielding , resistant to corrosive inks, use to repair copper base alloy parts.

CuAl-90/10 is a copper alloy with 90% copper and 10% aluminum, which makes it a versatile material for a range of applications.

The brand options include KF-320, KF-325, KF-321, and more.

One of the primary uses for CuAl-90/10 is in the repair and maintenance of copper and copper alloy components. Its properties make it an excellent choice for soft support surfaces for bearings. Additionally, CuAl-90/10 is often used in aviation components and air compressors due to its high electrical and thermal conductivity. It is also non-magnetic and useful for EMI shielding, making it an ideal choice for electronic equipment.

Another advantage of CuAl-90/10 is its resistance to corrosive inks, which makes it a suitable material for applications in the printing industry. It can also be used to repair copper base alloy parts, further highlighting its versatility.

In terms of its mechanical properties, CuAl-90/10 offers good wear resistance and high strength, making it a durable and long-lasting material. It is also easy to machine and weld, allowing for easy fabrication and repair work.

Overall, CuAl-90/10 is an excellent choice for a range of applications due to its combination of mechanical, electrical, and thermal properties. Its versatility makes it a valuable material for various industries, including aviation, electronics, and printing.

Similar products

| Brand | Product Name | AMPERIT | METCO/AMDRY | WOKA | PRAXAIR | PAC |

| KF-320 | CuAl-90/10 | 511004 | CU114CU104 | 16 | ||

| KF-325 | CuAl-90/10 | 511004 | CU114CU104 | 16 | ||

| KF-321 | CuNiIn | 58 | CU101CU102 | 658 |

Specification

| Brand | Product Name | Chemistry (wt%) | Hardness | Temperature | Properties & Application | ||||

|---|---|---|---|---|---|---|---|---|---|

| Al | Ni | In | Fe | Cu | |||||

| KF-320 | CuAl-90/10 | 10 | ≤1.0 | Bal. | HRC < 20 | ≤ 400ºC | •Size repair of copper and copper alloy components, soft support surface for bearings | ||

| KF-325 | CuAl-90/10 | 10 | 0.7-1.5 | Bal. | HRC < 20 | ≤ 400ºC | •Size repair of copper and copper alloy components, soft support surface for bearings | ||

| KF-321 | CuNiIn | 36 | 5 | Bal. | HRC < 20 | ≤ 400ºC | •Aviation components, air compressor | ||